From OEM manufacturing to the creation of the LC brand.

Chang Lien-Cheng Saxophone Co., Ltd. has been established for 80 years since its inception.

As determined innovators, we have developed and designed new copper alloys, connecting rods, surface treatment methods and lightweight packaging. The company has inherited the spirit of Mr. Chang Lien-Cheng, whom shouldered the responsibilities of researching, promoting, innovating and development of the saxophone industry in Houli.

We look forward to leading the Taiwanese saxophone industry with our expertise and transform it from being traditional OEM manufacturers to a culturally significant, highly-valued service industry. We hope to create a real value of Taiwan in the global music industry! Our saxophones can be customized and designed in order to meet the specific needs of different individuals, thus enhancing the quality of one’s life and benefiting the entire humanity as a whole.

With our specialty in saxophone manufacturing and sales experience, our design goals and strategies focus on alloy material analysis and product sound improvement. In addition we are also working with the Industrial Research Institute to develop new materials to improve our market competitiveness. Below are some of the awards received for new material development.

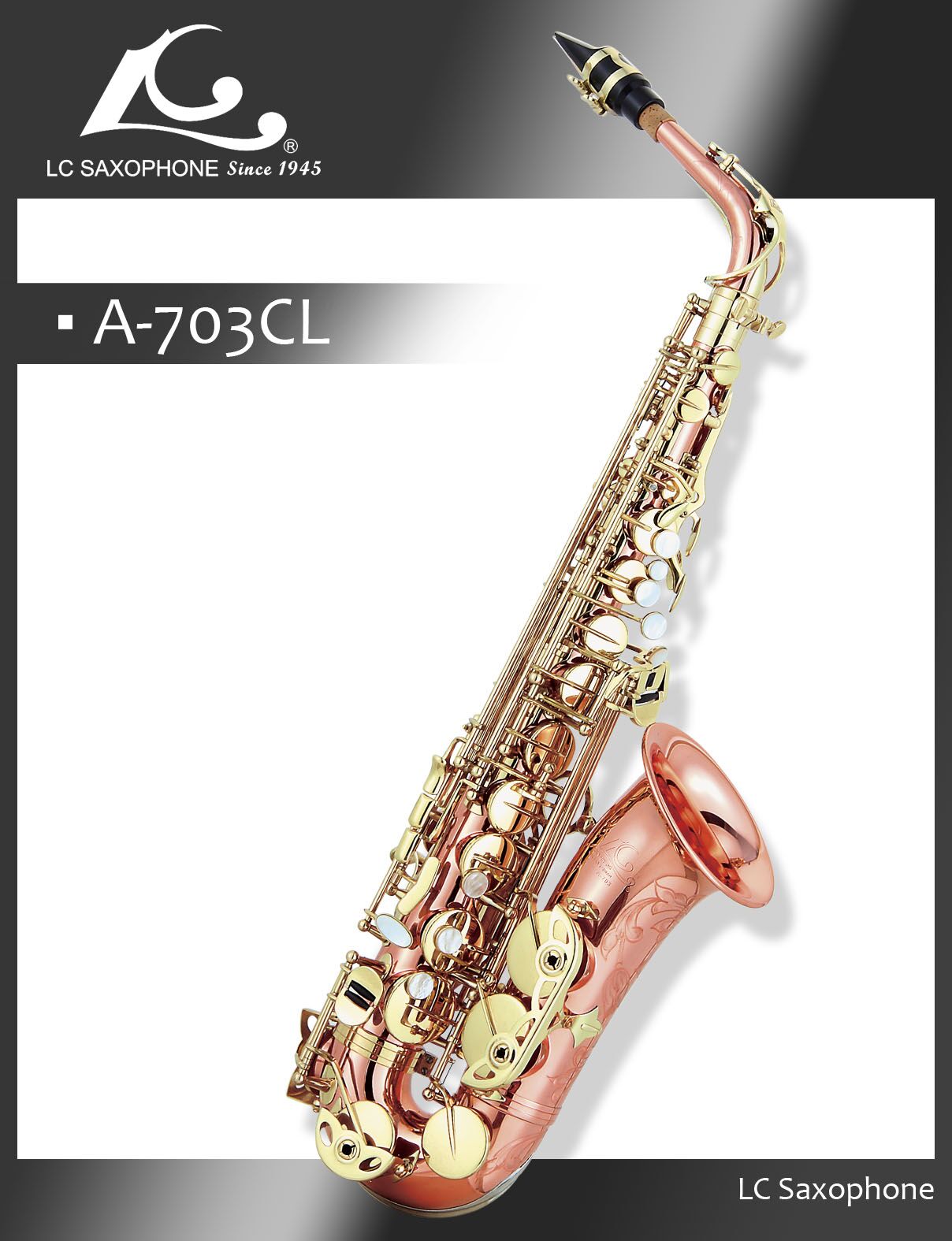

2013 Taiwan Excellence Award:98% red copper

2014 Taiwan Excellence Award: Silver alloy and white copper

We aim to establish a standardized manufacturing and quality control process to reduce production loss and manufacturing costs. This will improve our market competitiveness while simultaneously enable us to provide a wide-ranging array of customizable solutions.

2018 Taiwan Excellence Award

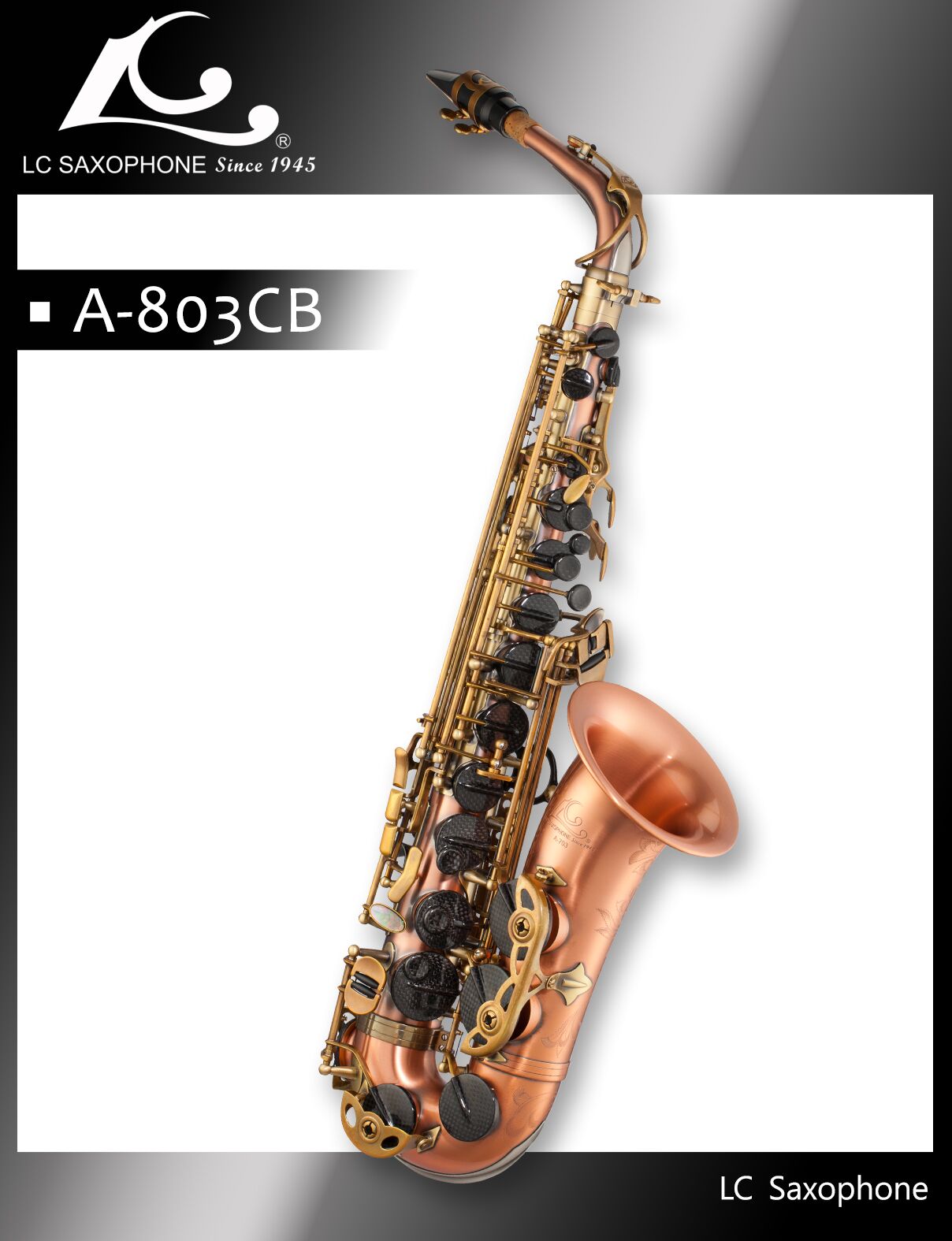

The most important aspect to making a saxophone is material selection and quality craftsmanship.At the present, saxophones produced both domestically and internationally utilize different proportions of copper alloy to produce different tones and resonance. In the material development aspect, we have collaborated with the Industrial Research Institute to research the production of saxophone parts (key cups, key posts, rods, etc.) using high-tech carbon fiber composite materials, resulting in a lighter saxophone without compromising its tone.

We were given the 2018 Taiwan Excellence Award for developing the world's first carbon fiber saxophone. Its advantages include:

- Special copper alloy material that provides a fuller and more elegant sound

- Chic and stylish retro design

- Faster key response and weight reduction

- Increase in structural integrity and decrease in abrasion and deformation

- A timeless design that is easy to service and maintain

This new design and development is a major breakthrough for the saxophone industry because it allows for smoother key actions and improvements in ergonomics.